Flannery has extended its working relationship with Spillard Safety Systems, to help it reduce accidents on site and keep workers safe.

Flannery, which has more than 1700 operators supporting its nationwide client base, has invested in ‘SpillardLive’, fitting it to 180 machines so that it can benefit from the human detection system, 360-degree cameras and real time feedback on driver performance.

The cloud-based platform captures and streams real-time video and analytics from multiple cameras fitted to plant equipment and vehicles. It has been developed in collaboration with Flannery to have the maximum impact, with feedback on trials enhancing many of the features of the system.

With up to 5200 machines in its fleet, Flannery is now planning to roll-out the technology to the rest of its equipment over the next three years.

“I’m delighted we have been able to expand our working relationship with the team at Flannery - the difference the initial roll-out has made is significant and will only grow as more operators are trained on the system,” explained Pete Spillard, managing director of Spillard Safety Systems.

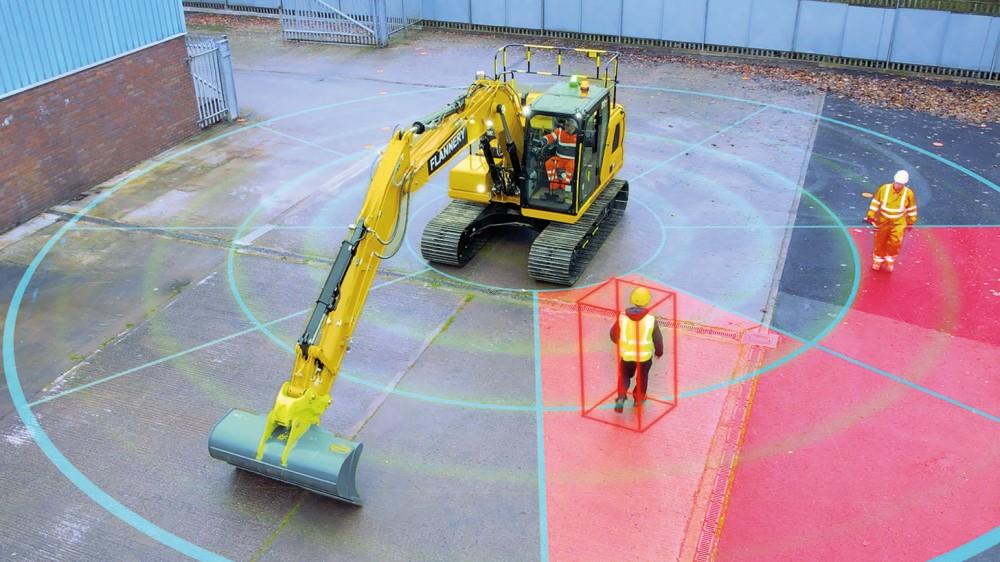

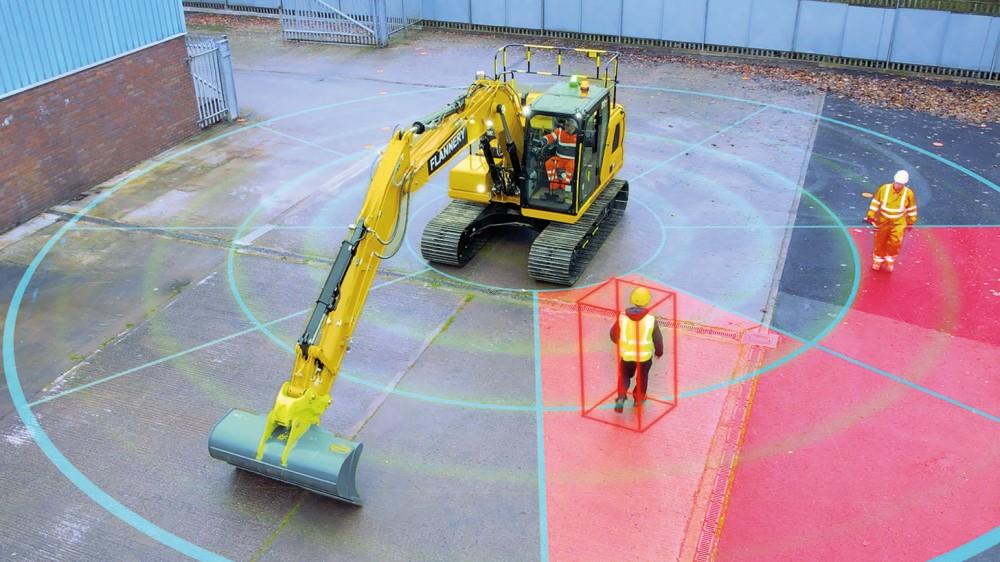

He continued: “When the ignition is switched on, these cameras can virtually map out a five-metre ‘red zone’, a further away ‘amber zone’ and a ‘green zone’ that indicates a safe distance. The data for that machine can be accessed from our platform and the live journey of that vehicle can be checked.

“This system means that a machine can track patterns and help highlight where changes need to be made on site. For example, a machine could detect that a person has encroached into the dedicated ‘red zone’ around fifty times at around three o’clock each day."

Patrick Flannery, Director of Flannery added: “The safety of our operators and those of our clients using our vehicles is paramount, which is why we’ve entered into this agreement with Spillard to incorporate ‘SpillardLive’ onto 180 of our vehicles and equipment.

“Initial results have been very encouraging; we’ve already been able to reduce the number of Plant People Interface (PPI) risks on sites, as well as identifying lots of ways we can train our staff to be better and safer, especially in human detection whilst operating the vehicles.”

The plant hire specialists are one of 300 companies that have signed up to SpillardLive, with 12,000 vehicles already connected and enjoying the huge benefits of the platform.

Find out more and meet the Spillard team on stand B-BA3 at Plantworx, from June 13-15.

www.spillard.com