With construction materials and equipment still beset by skyrocketing costs and/or snarled up en route to the UK, HSC MD Gary McWilliam has sought to explain how the company is tackling the current disruption in the worldwide supply chain.

"We have spent the last year enhancing our internal systems and procedures which has provided efficiencies whilst still keeping our systems robust and commercially efficient, these efficiencies have helped us to absorb a percentage of the price increases incurred over the last year without having to pass many increases on," he begins.

"We are only increasing prices when new stock makes its way in to our supply chain, if the stock was already in our warehouse prior to the raw material price increases, container price raises, and general chaos surrounding importing products we are all having to deal with we have not altered the price"

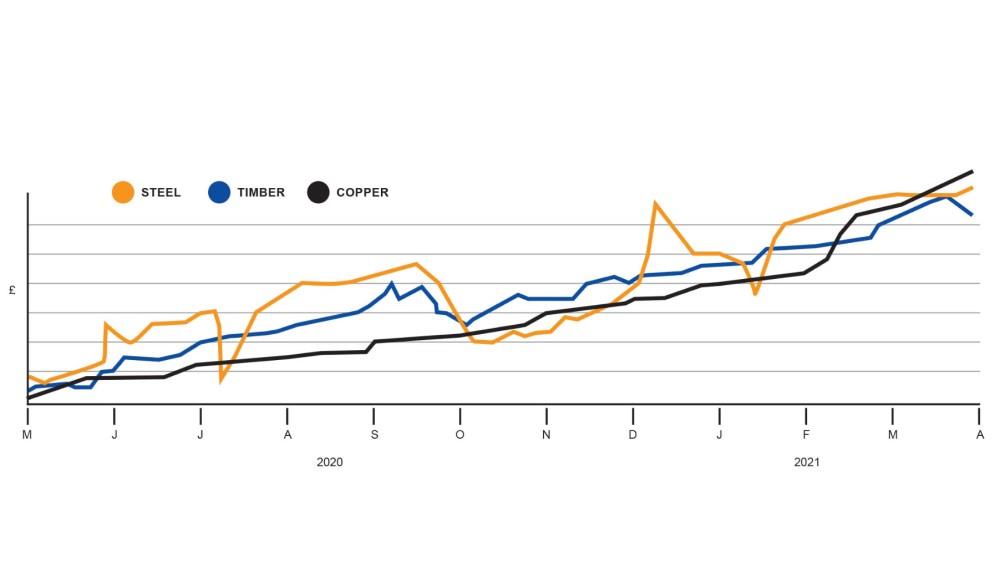

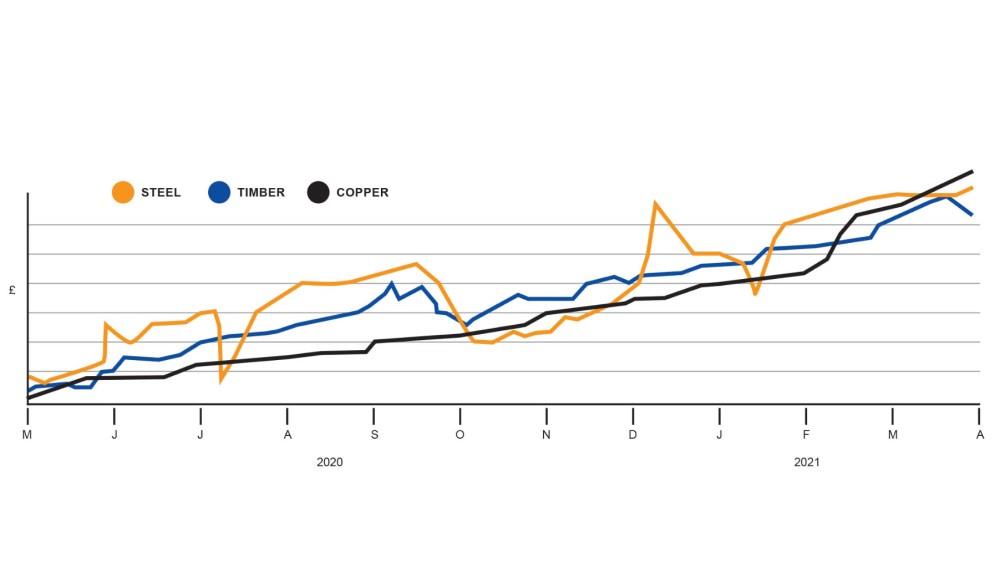

As the data in the graph above shows, raw core material costs have increased steadily over the last 12 months.

Gary continues: "As we maintain a lean supply chain and sometimes a just in time supply, we rotate our stocks on average 4 – 6 times a year this unfortunately means that every 2 – 3 months we need to replenish stocks. This is when we are hit with ever increasing prices which we have no option other than to pass on. We will endeavour to pass on the minimum increase possible and try and absorb the lion's share ourselves.

"To maintain a continuity of supply we source products from many different suppliers within Europe obviously

ensuring that the product you receive is safe, reliable and of the quality you expect from HSC.

"We have forward orders with our core suppliers that will enable us to continue fulfilling your orders but

unfortunately it might take us longer than normal. We are working closely with our suppliers and couriers who

are themselves facing unprecedented issues, we will continue to provide the best possible service we can

and be honest and open about our capabilities."